The fastest growing kind of electroless plating. The plating bath generally uses nickel sulfate, nickel acetate is major using salt, hypophosphite, sodium borohydride, borane, hydrazine, etc. Work in an acidic solution at 90°C or a neutral solution or alkaline solution at a temperature close to room temperature. It can be divided into two categories: electroless nickel-phosphorus plating and electroless nickel-boron plating based on the difference in reducing agent used. The coating shows superiority in uniformity, corrosion resistance, hardness, solder ability, magnetism, and decoration.

Hard chromium plating is generally applied to the surface of the product position of the mold. After chromium plating treatment, the mold and workpiece will have the advantages of smooth, smooth surface, easy demoulding, and no rust.

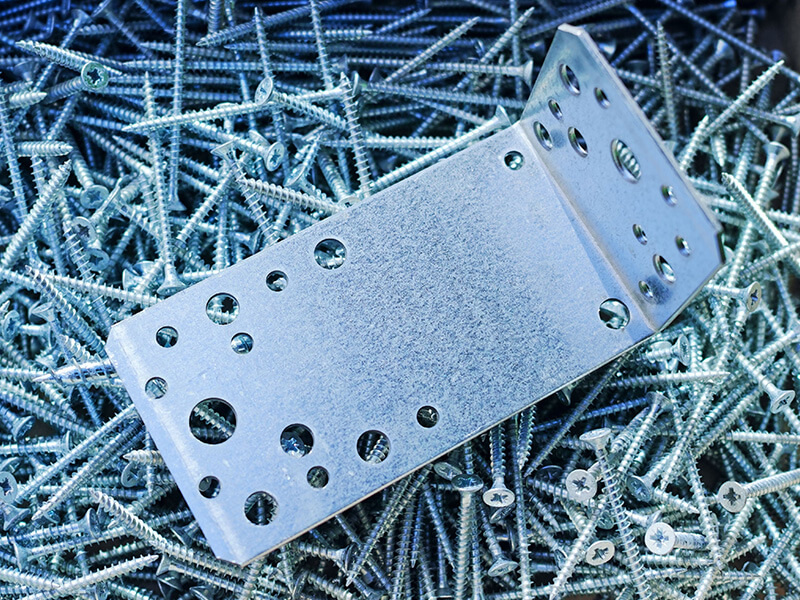

Electro-galvanizing, also known as cold galvanizing in the industry, is the process of using electrolysis to form a uniform, dense, and well-bonded metal or alloy deposition layer on the surface of the part. Compared with other metals, zinc is a relatively cheap and easily plated metal. It is a low-value anti-corrosion electroplating layer and is widely used to protect steel parts, especially to prevent atmospheric corrosion, and for decoration. Plating technology includes slot plating (or rack plating), barrel plating (suitable for small parts), blue plating, automatic plating and continuous plating (suitable for wire and strip)

Our team is on hand to address your concerns.

Just complete the email form below.

Thank You!

© 2024 Iceberg Thermal Inc. All rights reserved