Description

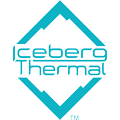

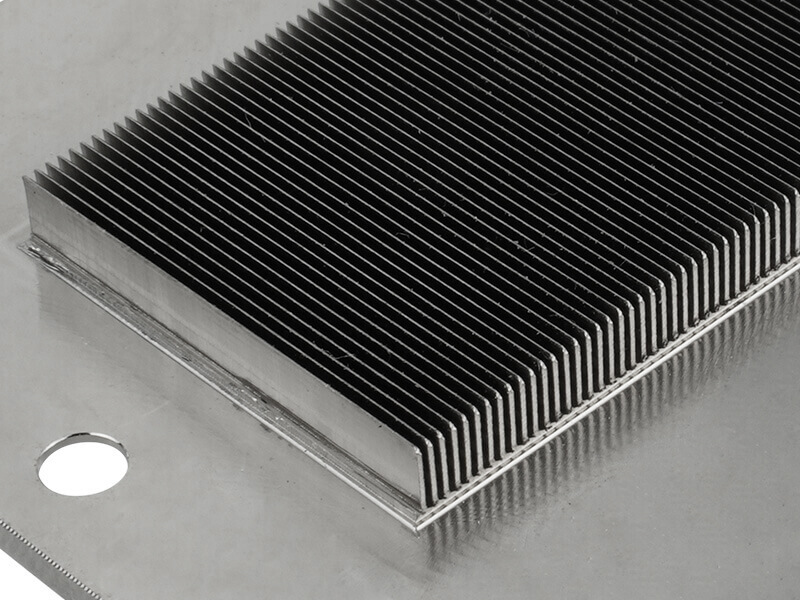

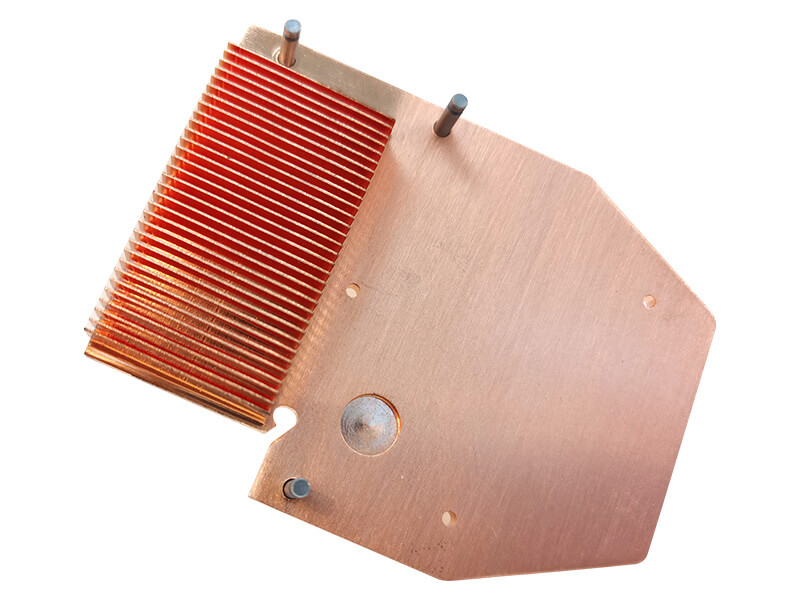

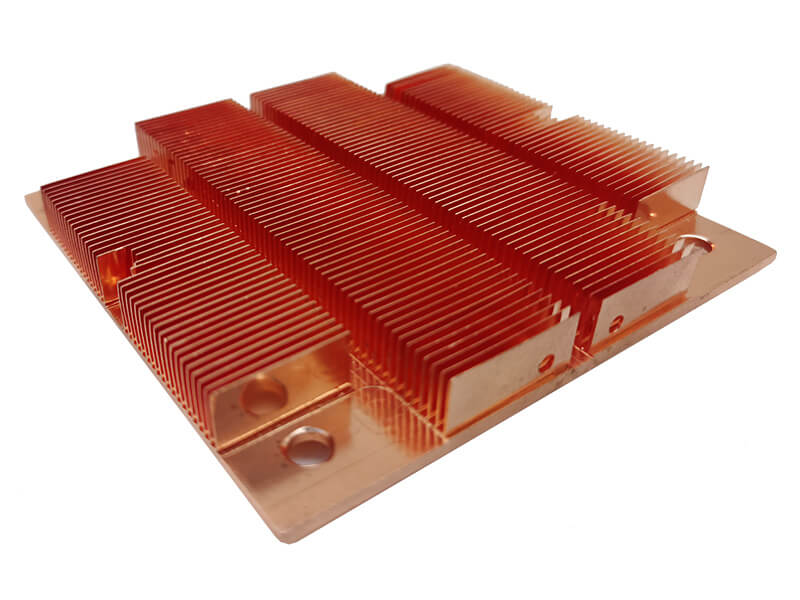

SHOVEL TOOTH

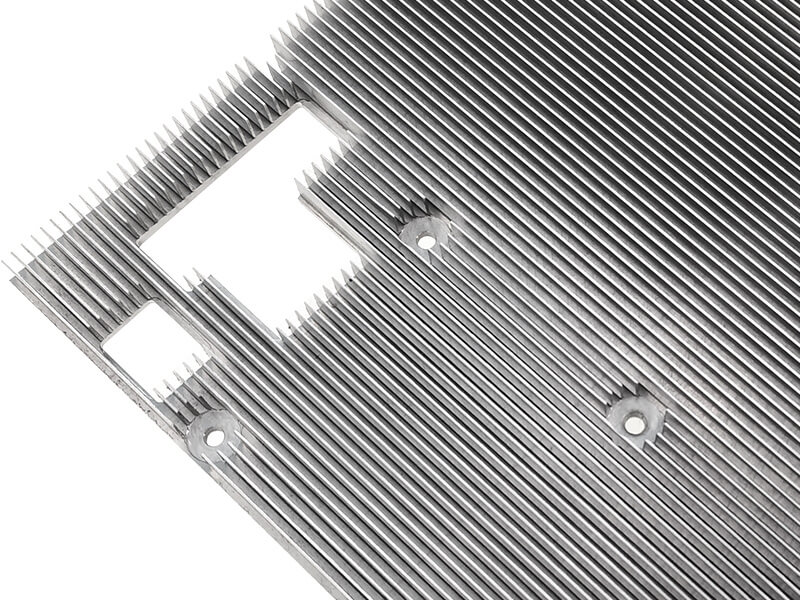

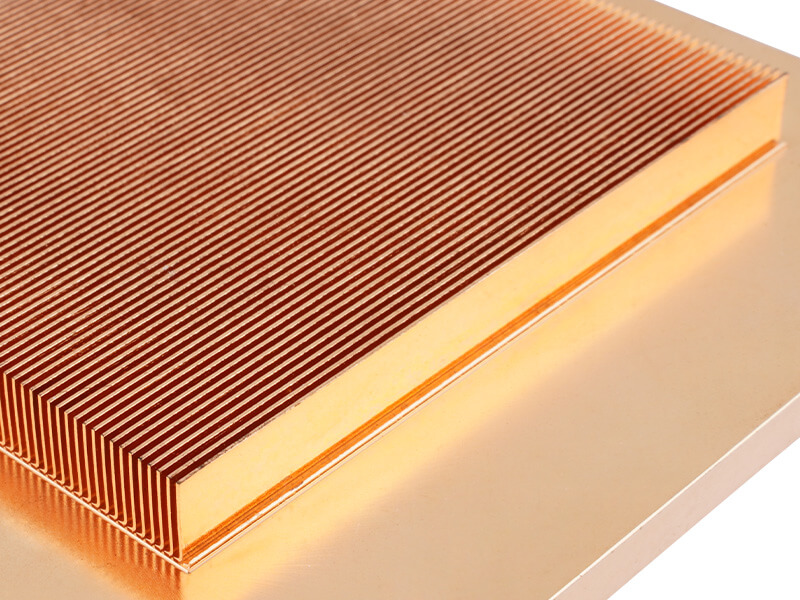

SHOVEL LATHE

The spade tooth process is used to make heat sinks and is mostly used for heat dissipation of high-power parts. Because it has a one-time molding, does not lose the heat dissipation performance of the profile, it reaches 100% of the original heat dissipation performance of the profile, and it also has the characteristics of large size and high power. High-power motors are widely used. It is mostly used in large radiators such as photovoltaic inverters, wind power converters, electric vehicle controllers, and power battery packs. The shovel process can also be used with other heat dissipation processes, such as the heat pipe process mentioned above, and can also be combined with water-cooling plate technology, micro-channel technology, etc., according to the characteristics of different motors to make radiators of different shapes and sizes, with different combinations The technology can improve the performance of the radiator while reducing costs. The shovel teeth do not require high profile materials, and they can be aluminum or copper profiles.

CONTACT US

Our team is on hand to address your concerns.

Just complete the email form below.

Thank You!