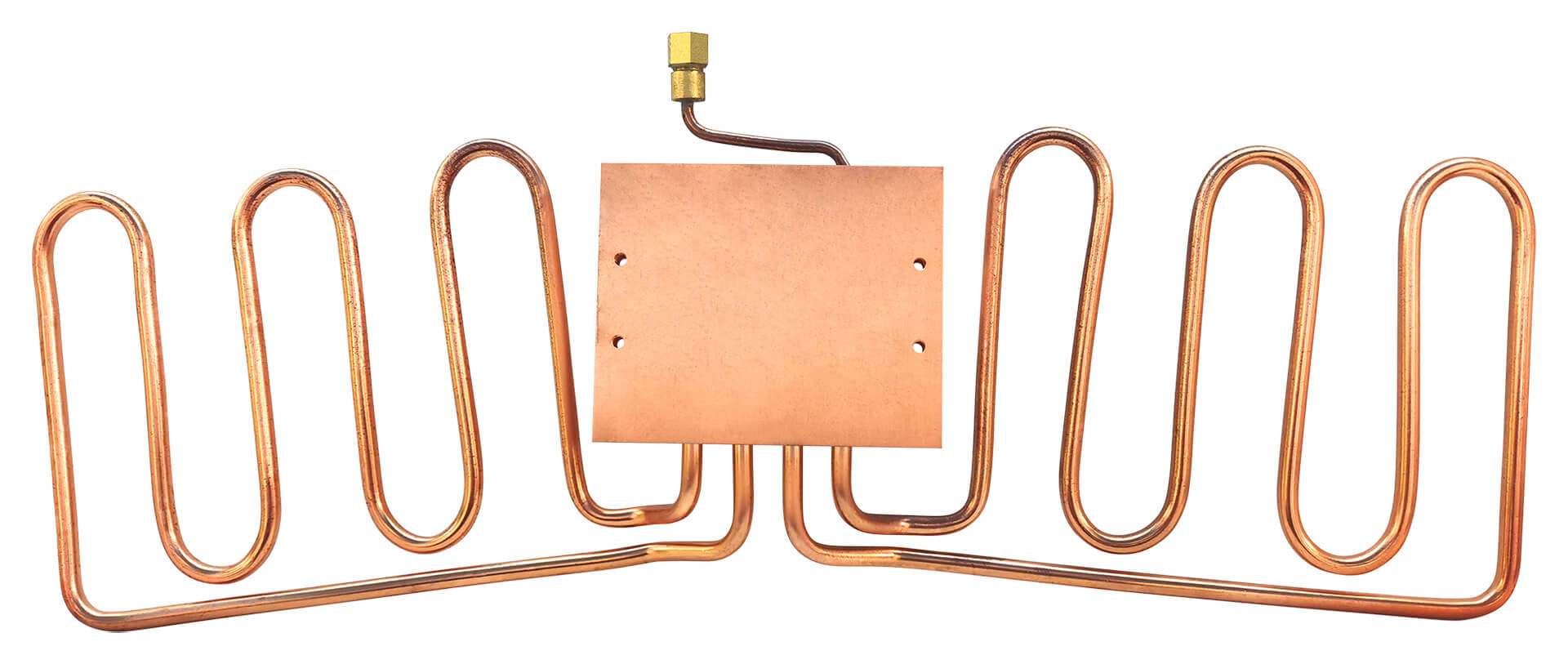

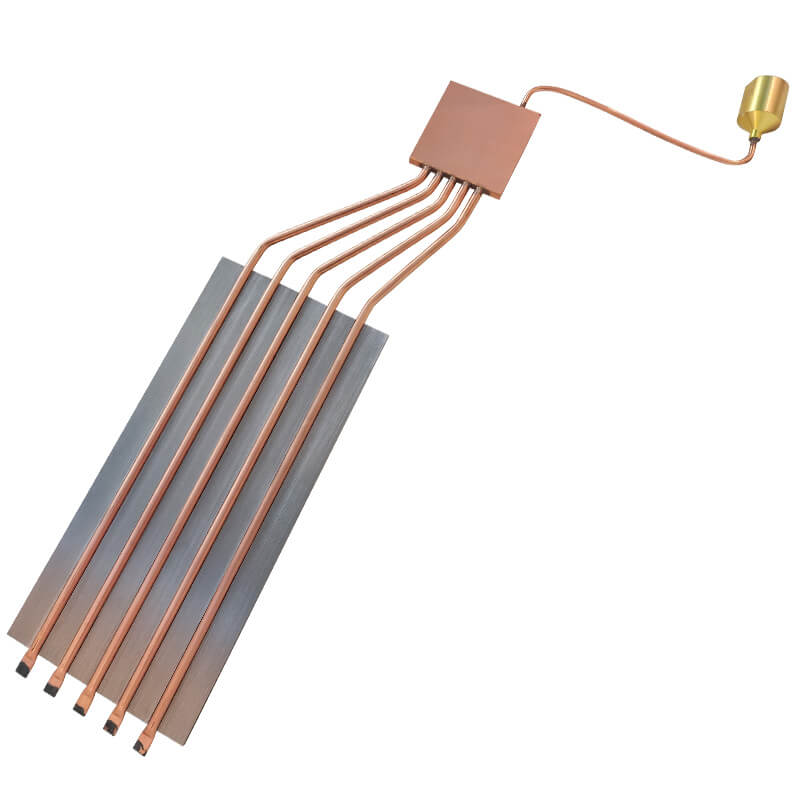

Description

COPPER PIPE HIGH FREQUENCY SOLDERING

HIGH FREQUENCY PIPE WELDING MACHINE

High-frequency welding refers to a welding method that uses high-frequency current to flow through the resistance heat generated by the contact surface of the workpiece, and applies pressure (or no pressure) to connect the metal of the workpiece. Generally, the frequency of high-frequency welding is selected in the range of 300 to 450 kHz. High-frequency welding can be divided into contact high-frequency welding and induction high-frequency welding according to the way that high-frequency current generates heat in the workpiece. When contacting high-frequency welding, high-frequency current flows into the workpiece through mechanical contact with the workpiece. During induction high-frequency welding, the high-frequency current generates an induced current in the workpiece through the coupling action of the outer induction coil of the workpiece. High-frequency welding is a highly specialized welding method, which must be equipped with special equipment according to the product. The productivity is high, and the welding speed can reach 30m/min. Mainly used for welding longitudinal seams or spiral seams when manufacturing pipes.

CONTACT US

Our team is on hand to address your concerns.

Just complete the email form below.

Thank You!